1.Material: 77% cotton 18% polyester 5% spandex 2.Color : orange,blue,black,red,white or as customized 3.Size : men or as customized 4.MOQ : 1000 pairs / color 5.Logo : customized your company or brand logo

1. Material: 75% cotton 20% polyester 5% spandex 2. Color: green, red or as custom 3.Size: women, girls or as customized 4.MOQ: 1000 pairs / color 5.Logo: personalized your company or logo brand

1. Material: 75% cotton 20% polyester 5% spandex 2. Color: green, red or as custom 3.Size: women, girls or as customized 4.MOQ: 1000 pairs / color 5.Logo: personalized your company or logo brand

1.Material: 83% cotton 12% polyester 5% spandex 2.Color : khaki, blue, yellow, pink, green, grey, purple or as customized 3.Size : 0-6 month,6-12 month,1-3 years baby or as customized 4.MOQ : 1000 pairs / color 5.Logo : customized your company or brand logo

1.Material: 83% cotton 12% polyester 5% spandex2. Color: black, red, white or customized3.size: adult or as a custom4.Moq: 1000 pairs / color / size5.Logo: Custom your company or brand logo

1.Material: 83% cotton 12% polyester 5% spandex2. Color: black, red, white or customized3.size: adult or as a custom4.Moq: 1000 pairs / color / size5.Logo: Custom your company or brand logo

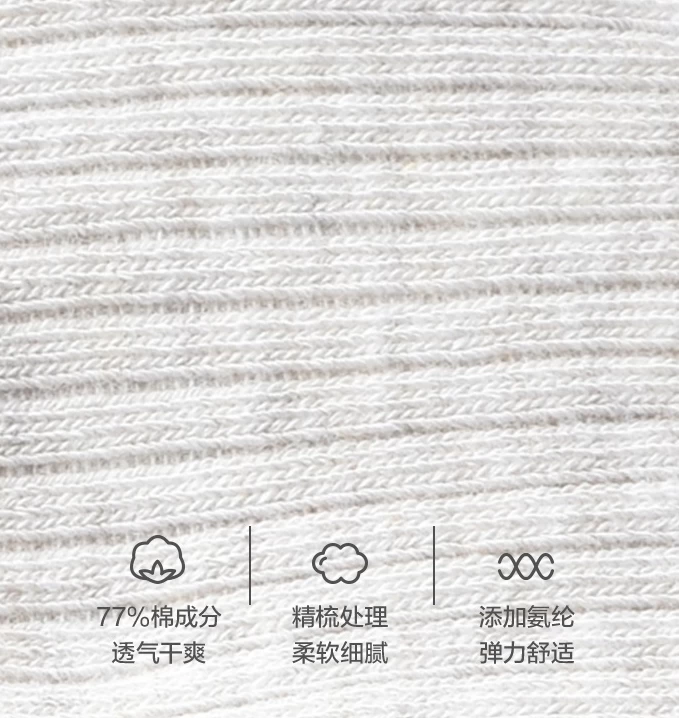

Commonly used are cotton, bamboo fiber, hemp fiber, various animal hair fibers such as wool, rabbit hair, etc., the higher the main component, the higher the cost, and the more comfortable it is to wear.

2.Polyester fiber: polyester, also used synthetic fiber of nylon cotton, used to strengthen the wear resistance of socks, the general content is 15% -20%.

3. Elastic fiber: spandex, also used in high-end Lycra, used to add elasticity to socks, generally in the range of 3%-8%.

4. According to the yarn weaving and textile process, it is divided into combed cotton and carded cotton. It is the carded cotton that does not indicate the combed cotton on the ingredient label.

The combed cotton here is a yarn that is cleaned by the specific machine to clean the impurities in the cotton yarn, so the combed cotton socks are more textured and more durable than the carded cotton.

Many people like cotton socks. There are no 100% cotton on the market. Cotton socks are not elastic, not wearable, and uncomfortable to wear. Generally, cotton socks with a content of more than 85% can be considered as full. Cotton is gone.

Cotton fiber is easy to deform and harden after washing many times. For this market, bamboo fiber, hemp fiber, bamboo fiber, bamboo fiber are more expensive than cotton socks. In essence, it should be called bamboo pulp fiber. A kind of fiber extracted after pulp, the hand feels better, the gas permeability and water absorption can also be, it will not be hard after washing, the shortcoming is also essential, the wear resistance is not good, and it is easy to pilling after rubbing.

custom design socks manufacturers